Day 3 :

Keynote Forum

Saba Abdulghani Oliveira da Silva

CDRSP-IPLeiria, Portugal

Keynote: A framework of materials for 4d printing

Time : 09:00-09:25

Biography:

Saba Abdulghani Oliveira da Silva is a researcher at the Centre for Rapid and Sustainable Product Development at the Polytechnic Institute Leiria (IPL), Portugal. Saba carried out her Bachelor of Engineering degree (B.Eng) and Doctorate degree (PhD) at the Materials Department of Queen Mary University of London in Biomaterials under the supervision of Professor K.E. Tanner. Following her PhD, Saba was awarded a Marie Curie Intra-European Post-Doctoral Fellowship to work on the Biomechanics of cemented hip prostheses at the Biomaterials and Biomechanics Laboratory, Lund University Hospital, Sweden under the supervision of Professor Lars Lidgren. In 2008, Saba moved to Portugal to work at the Rheumatology research unit, Instituto de Medicina Molecular (IMM) on the mechanical properties of osteoporotic bone, for which she won a research award from the European Calcified Tissue Society (ECTS/ Servier International Award 2010). Saba´s research experience covers orthopaedic biomaterials and biomechanics as well as the mechanics of healthy and diseased bone. She has her work published in international journals and has presented her work at international conferences all over the world and is a reviewer for a number of International journals. Her current research interests are 3D and 4D scaffolds for tissue engineering, AM and biomechanics.

Abstract:

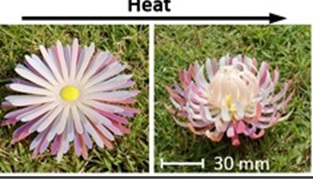

4D printing is a term used in additive or direct digital manufacturing to describe a process in which a part is prepared with a particular form and then when stimulated by changes in temperature, humidity, light and pH transforms in to another shape. Such an approach is a revolutionary idea in manufacturing. The opportunities are endless. Figure 1 shows an example from the literature. For example object can be prepared to make manufacturing facile, transport costs minimal and then converted in to the finished object at the point of use. Clearly this technology has much to offer to medical devices and we can envisage an object which is printed in a form to make it easy to insert in to the body by, for example a hypodermic needle, which then at body temperature opens up in to a 3d structure to close an internal injury, implant a tissue for regenerative purposes or to deliver some therapeutic agent. In this presentation we present a framework for 4d printing which enables us to classify different types of shape or form changes. We review the stimuli driven materials available and hence the molecular mechanisms available to deliver 4D printing technology with temperature and light activation. We take examples from the literature and identify the most promising molecular mechanisms and identify the potential for applications.

This work is supported by the Fundação para a Ciência e a Tecnologia (FCT) through the Project references: UID/Multi/04044/2013; PAMI - ROTEIRO/0328/2013 (Nº 022158) and MATIS (CENTRO-01-0145-FEDER-000014 - 3362).

Figure 1: An example of a 4d printed structure which changes shape on heating. The flower is prepared from a shape memory polymer. Photo reproduced under a Creative Commons Attribution Non Commercial License 4.0 (CC BY-NC) from Zhen Ding, Chao Yuan, Xirui Peng, Tiejun Wang, H. Jerry Qi and Martin L. Dunn Science Advances 12 Apr 2017: Vol. 3, no. 4, e1602890 DOI: 10.1126/sciadv.1602890

Recent Publications

1. A. Sydney Gladma, Elisabetta A. Matsumoto, Ralph G. Nuzzo, L. Mahadevan & Jennifer A. Lewis. Nature Materials volume 15, pages 413–418 (2016).

2. Qi Ge, Amir Hosein Sakhaei, Howon Lee, Conner K. Dunn, Nicholas X. Fang, Martin L. SCIENTIFIC Reports 2016 6:31110 DOI: 10.1038/srep31110.

3. Morouço,P., Lattanzi, W., & Alves, N. (2017). 4D Bioprinting as a new era for tissue engineering and regenerative medicine. Frontiers in Bioengineering and Biotechnology, 5, 61.

4. Zhen Ding, Chao Yuan, Xirui Peng, Tiejun Wang, H. Jerry Qi2,† and Martin L. Dunn Science Advances 2017: Vol. 3, no. 4, e1602890 DOI: 10.1126/sciadv.1602890.

5. Steven K. Leist & Jack Zhou (2016) Current status of 4D printing technology and the potential of light-reactive smart materials as 4D printable materials, Virtual and Physical Prototyping, 11:4, 249-262, DOI: 10.1080/17452759.2016.119863.

Keynote Forum

Aman Ullah

University of Alberta, Canada

Keynote: Development of biopolymers and biomaterials from lipids

Time : 09:25-09:50

Biography:

Aman Ullah received his PhD (with distinction) in Chemical Sciences and Technologies in 2010 at the University of Genova, Italy by working together at Southern Methodist University, USA. He worked as a postdoctoral fellow before accepting an Assistant Professor position at the University of Alberta. He has recently developed and is teaching a new graduate course entitled “Renewable Biomaterials”. This course deals with fundamentals in bio-based materials development, characterization, and various industrial applications. Current research, recent literature, and real-life applications of biomaterials/bionanomaterials in various industries are discussed throughout the course. Aman has published more than 45 papers in reputed journals and 3 patents/patent applications. He was named a Canadian Rising Star in Global Health by Grand Challenges Canada in 2012.

Abstract:

In recent years, the use of renewable natural resources have become the focus of research in supplementing and replacing traditional petrochemical products due to growing energy demands and environmental concerns. The utilization of lipids has been considered to play a primitive role towards sustainable development due to their large scale availability, built-in-functionality, biodegradability and no net CO2 production. In addition, a broad range of monomers can be obtained from lipids as a single feedstock. These attributes make lipids a good fit for the development of renewable biomaterials. This Presentation will focus on the conversion of lipids, from various sources including waste streams such as waste cooking oil and lipids extracted from spent foul, into monomers, biopolymers and bionanocomposites using our patented technology. The ability for complete conversion of oils in just few minutes under solvent free conditions into monomers, biopolymers and bio-nanocomposites is undoubtedly an attractive concept from both an academic and an industrial point of view.

Recent Publications

1. Jin, L.; Zeng, H.; Ullah, A. Rapid Copolymerization of Canola Oil Derived Epoxide Monomer with Anhydrides and Carbon Dioxide (CO2), Polymer Chemistry, 2017, Accepted DOI: 10.1039/C7PY01429E.

2. Jin, L.; Geng, K.; Arshad, M.; Ahmadi, R.; Ullah, A. Synthesis of Fully Biobased Polyesters from Plant Oil, ACS Sustainable Chemistry & Engineering, 2017, In Press; http://dx.doi.org/10.1021/acssuschemeng.7b01668.

3. Ahmadi, R.; Ullah, A. Microwave-assisted rapid synthesis of a polyether from a plant oil derived monomer and its optimization by Box–Behnken design, RSC Advances, 2017, 7, 27946–27959.

4. Ullah, A.; Arshad, M. Remarkably Efficient Microwave-Assisted Cross-Metathesis of Lipids in Solvent Free Conditions, ChemSusChem, 2017, 10, 2167-2174.

5. Arshad, M‡.; Pradhan, RA.; Ullah, A., Synthesis of lipid-based amphiphilic block copolymer and its evaluation as nano drug carrier, Mater. Sci. Eng. C., 2017, 76: 217-223.

Keynote Forum

Dmitry Volodkin

Nottingham Trent University, United Kingdom

Keynote: Two- and three-dimensional multilayer bio-coatings as novel drug delivery systems. From nano to micro

Time : 09:50-10:15

Biography:

Dmitry Volodkin is Associate Professor at Nottingham Trent University and heads the group “Active-Bio-Coatings”. He has studied Chemistry at the Lomonosov Moscow State University in Russia. Research stays brought him to France (University of Strasbourg) and Germany (Max-Planck Institute of Colloids and Interfaces, Technical University of Berlin, Fraunhofer Institute for Cell Therapy and Immunology). His research activities are focused on design of advanced stimuli-responsive biomaterials for applications in tissue engineering, diagnostics, toxicology, drug delivery. His group engineer self-assembled polymer-based 2D and 3D structures with tailor-made properties: multilayer films, microcapsules and beads, liposome-polymer composites, polymeric scaffolds, etc. Dmitry Volodkin has published more than 70 peer-reviewed articles/books and received a number of prestigious scientific awards such as Sofja Kovalevskaja Award of Alexander von Humboldt Foundation, Richard-Zsigmondy Price of German Colloid Society, Alexander von Humboldt Fellowship, Marie SkÅ‚odowska-Curie Fellowship.

Abstract:

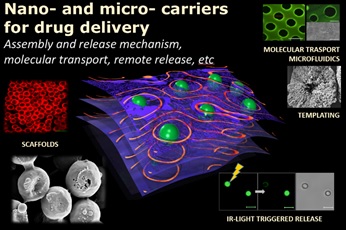

Polymer multilayers first introduced about two decades ago are nowadays widely used towards bio-applications in tissue engineering and regenerative medicine. Our research is focused on active 2D and 3D multilayer structures (e.g. planar films, capsules, beads) with tailor-made properties. Such structures have a fine-tuned architecture, controlled thickness from nano to macro, adjusted softness from Pa to GPa, almost unlimited variety of functional components, and externally activatable drug release. In this talk I present our recent findings in mild and effective immobilization of biomolecules (proteins, nucleic acids, small drugs, etc) and approaches for release/delivery the biomolecules in a controlled manner. The externally triggered release on demand by IR-laser light and cell biology studies including extra- and intra-cellular delivery will be considered. The developed structures offering localized, remote, and non-invasive release of biomolecules are indispensable for applications in tissue engineering, and especially for single cell studies where high precision of delivery in space and time is highly desirable.

Recent Publications

1. Volodkin D & von Klitzing R (2014) Competing mechanisms in polyelectrolyte multilayer formation and swelling: Polycation–polyanion pairing vs. polyelectrolyte–ion pairing. Curr Opin Colloid Interface Sci 19: 25-31.

2. Volodkin D (2014) CaCO3 templated micro-beads and -capsules for bioapplications. Adv Colloid Interface Sci 207: 306-324.

3. Prokopovic VZ, Duschl C & Volodkin D (2015) Hyaluronic Acid/Poly-l-Lysine Multilayers as Reservoirs for Storage and Release of Small Charged Molecules. Macromol Biosci 15: 1357-1363.

4. Vikulina AS, Anissimov YG, Singh P, Prokopovic VZ, Uhlig K, Jaeger MS, von Klitzing R, Duschl C & Volodkin D (2016) Temperature effect on the build-up of exponentially growing polyelectrolyte multilayers. An exponential-to-linear transition point. PCCP 18: 7866-7874.

5. Prokopovic VZ, Vikulina AS, Sustr D, Duschl C & Volodkin DV (2016) Biodegradation resistant multilayers coated with gold nanoparticles. Towards tailor-made artificial extracellular matrix. ACS Applied Materials & Interfaces 8: 24345-24349.

Keynote Forum

Nuno Alves

CDRSP-IPLeiria, Portugal

Keynote: Optimising the acceleration of cell proliferation in a bioreactor for scaffold-based tissue engineering

Time : 10:15-10:40

Biography:

Nuno Alves is the Director of the Centre for Rapid and Sustainable Product Development (CDRSP), which is dedicated to the transformation of the manufacturing industry through the development and implementation of novel Additive Manufacturing (AM)/three/four-dimensional (3D/4D) printing technology. He is an Associate Professor on Computer Modelling and Simulation at the Polytechnic Institute of Leiria (PIL). His research interests are based on the development and exploitation of novel direct digital manufacturing systems, contributing for the new paradigm of the industry 4.0 (as recently named new industrial and societal revolution), mainely based on additive manufacturing/printing techniques, including computer-aided modelling and fabrication of complex multi-material 3D and 4D structures (with spatio-temporal varying properties) for both industrial and biomedical applications; Computer vision and photogrammetry; Biomimetics and bioinspiration (learn from nature); Tissue engineering; Mould design and polymer injection moulding; Rapid product development; and Circular economy.

Abstract:

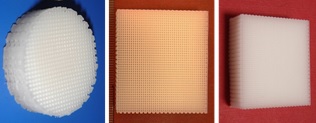

One of the most exciting areas in recent years has been regenerative medicine in which failed or damaged body parts are grown from the patients own cells loaded in to a porous scaffold. The scaffold is placed in to a bioreactor to accelerate the proliferation of the cells and when the tissue is partly formed the complete assembly is implanted in to the patient. It is fair to say that apart from isolated cases the promise has not transformed in to reality as a consequence of the limited proliferation rates. In this work we explore the use of computer modelling to optimize the stimulation processes used in the bioreactor to deliver enhanced rates of proliferation. Currently, mechanical stimuli are used in most of the studies allowing to accelerate the growth of cells placed on the scaffold inside the bioreactor. Some in-vitro studies have shown promising results when mechanical, electrical and magnetic stimulation are used either isolated or combined. Therefore, it is important to understand the gain of using these three type of stimulation. In this talk we will present the work that has been done at the Center for Rapid and Sustainable Product Development, regarding new biomaterials and the development of 3D biofabrication equipment to produce and host these scaffolds. The main focus is on computer modelling. We introduce a finite element analysis approach used to optimise the design of a new bioreactor allowing mechanical stimulation. We present the numerical results of the application of electrical stimulation in a biocompatible scaffold. We have performed the optimisation of the application of electrical stimulation when different electrode montages are used. The results have allowed us to gain a valuable insight on the influence of the different stimulation parameters involved.

This work is supported by the Fundação para a Ciência e a Tecnologia (FCT) through the Project references: UID/Multi/04044/2013; PAMI - ROTEIRO/0328/2013 (Nº 022158) and MATIS (CENTRO-01-0145-FEDER-000014 - 3362).

Figure 1 Examples of highly porous scaffolds produced by direct digital manaufacturing for use in tissue engineering [5].

Recent Publications

1. Paula Pascoal-Faria, Pedro Castelo Ferreira, Abhishek Datta and Nuno Alves (2018) Electrical stimulation optimization in bioreactors for tissue engineering applications. Advanced Materials Research in press.

2. Pedro Morouço, Sara Biscaia, Tânia Viana, Margarida Franco, Cândida Malça, Artur Mateus, Carla Moura, Frederico Ferreira, Geoffrey Mitchell and Nuno Alves (2016) Fabrication of Poly (e-caprolactone) Scaffolds Reinforced with Cellulose Nanofibers, with and without the Addition of Hydroxyapatite Nanoparticles. BioMed research international, vol. 2016, 1596157.

3. Rúben F. Pereira, Dino Freitas, Ana Tojeira, Henrique A. Almeida, Nuno Alves & Paulo J. Bártolo (2013) Computer modelling and simulation of a bioreactor for tissue engineering, International Journal of Computer Integrated Manufacturing, 27:10, 946-959.

4. Sara Biscaia, Emilia Dabrowska, Ana Tojeira, João Horta, Pedro Carreira, Pedro Morouço, Artur Mateus, Nuno Alves (2017 ) Development of heterogeneous structures with polycaprolactone-alginate using a new 3D printing system-BioMEDβeta: design and processing, Procedia Manufacturing, 12, 113-119.

5. Geoffrey R Mitchell, Marcos Domingos and Paulo Bártolo (2012) Polymers, Biomanufacturing and Regenerative Medicine, Advanced Materials Research, 2012 55-5733-362008.