Nazim Babacan

Gazi University, Turkey

Title: Influence of grain size on super elasticity and actuation properties of Cu-Al-Mn shape memory alloys

Biography

Biography: Nazim Babacan

Abstract

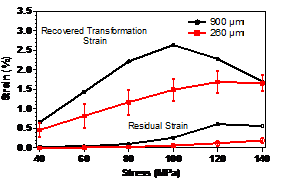

Grain size is one of the main microstructural parameters which dictate the shape memory properties of Cu-based shape memory alloys (SMAs). In this study, grain size control of Cu73Al16Mn11 (%) shape memory alloy was achieved via cold rolling–short time post annealing technique. While homogenized material has an average grain size of 900 µm, 260 µm average grain size was obtained after 70% rolling at room temperature and subsequent 950ºC 80 seconds heat treatment. Super elasticity and actuation properties of homogenized and thermo-mechanically treated material were compared by utilizing incremental cyclic tensile and isobaric heating-cooling experiments respectively. It was found that decreasing the grain size had no effect on the superelastic properties of the material, however, residual strains obtained from isobaric heating-cooling experiments decreased prominently. These two contradictory results can be explained by two mechanisms. Since stress level in super elasticity tests are higher (about 300 MPa when transformation starts) than that of in the case isobaric heating-cooling tests (maximum 140 MPa tension stress was applied), stress concentrations at the grain boundaries lead to intergranular fracture owing to high elastic anisotropy of the Cu-based SMAs. On the other hand, strengthening effect of grain size reduction is the main mechanism to increase the dimensional stability by impeding the motion of dislocations that occurs due to the martensitic transformation in isobaric heating-cooling experiments.

Figure 1: Recovered transformation strain and residual strain as a function of applied stress for materials that have different grain size