Ebru Saraloglu Güler

Baskent University, Turkey

Title: Internal stress and friction measurements during MoS2-nickel electrodeposition

Biography

Biography: Ebru Saraloglu Güler

Abstract

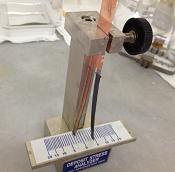

The electroplating method is a promising alternative to produce composite plating by using dispersed fine particles in the metal plating bath. The process can be either called electro co-deposition or composite deposition. The particles are trapped in the deposit during the process. Internal stress is a common problem in plated deposits that affect the performance of the coatings and may even result in adhesion problems. Hence, the amount and type (compressive or tensile) of the internal stress must be controlled. MoS2 particle-nickel coatings can be referred as self-lubricating coatings that satisfy the demand for decreased friction in severe applications. The internal stress during MoS2 particle-nickel electrodeposition was measured by deposit stress analyzer. The effects of electroplating parameters that are MoS2 particle concentration (0 and 10 g/l), temperature and coating thickness (25 and 50 µm) on the internal stress values were investigated by Taguchi design. It is found that increasing MoS2 particle concentration and coating thickness led to decrease in the internal stress developed during MoS2-nickel composite coatings. Interaction effects of these parameters were also revealed. The most effective parameter on internal stress was determined as MoS2 concentration by regression analysis. Therefore, three different MoS2 concentrations (0, 10 and 30 g/l) were studied in order to find out the concentration effect on the coefficient of friction and wear rate by pin-on-disc tribometer.