Ali Kalkanli

Middle East Technical University, Turkey

Title: Melt infiltration casting of alumina, silicon carbide and boron carbide reinforced aluminium matrix composites

Biography

Biography: Ali Kalkanli

Abstract

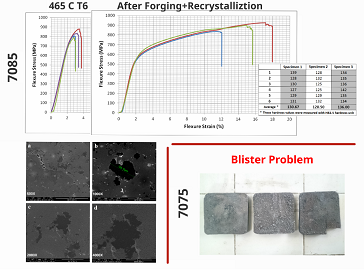

A series of metal matrix composites were produced using 7075 and 7085 aluminum alloys as matrix alloys and Al2O3, SiC and B3C4 seramic preforms. Melt infiltration casting was performed with a vertical squeeze caster applying 70 ton pressure during processing. Sintering of ceramic preforms were carried out at 1000, 1100 and 1300ºC for one hour then preheated hot sintered preforms at 1000ºC were placed into a die cavity before aluminum infiltration casting. During processing vertical 70 ton and upward 40 ton hold down pressure was applied for three minutes for melt infiltration. Mechanical characterizations were done by three point bending tests and flexure strength values obtains for 7075 alloy infiltrated Al2O3 preforms as 520-600 MPa.