Lev Rapoport

Holon Institute of Technology, Israel

Title: Deformation microstructure of surface layers of Ag, Cu, Ni and Al under friction in lubricant conditions

Biography

Biography: Lev Rapoport

Abstract

Friction and wear are the crucial problems affecting the life time of moving mechanical parts. The main goal of this work is to study: the evolution of the microstructure after friction with lubricant of four fcc metals (Ag, Cu, Ni and Al and the effect of stacking fault energy (ï§SFE) on grain size and wear loss. Friction surfaces were carefully examined with a field emission scanning electron microscope. The cross sectional TEM lamellae were prepared from the pins using a focused ion beam (FIB). Cross-sectioning of the specimens was done in the longitudinal and transverse directions (parallel and perpendicular to direction of friction).Deformation twinning followed by a limited recovery within a surface of Ag led to formation of relatively thick top layer of ultra-fine equiaxial grains. Surface regions of Cu and Ni samples consisted of inhomogeneous microstructure with wide range of grain sizes. With a depth lamellar structure was formed parallel to direction of friction for Ag, Cu and Ni. Subdivision of grains into subgrains with high dislocation density is clearly observed within a lamellar structure. Steady state values of grain size, ds and hardness, Hs after friction in lubricant conditions are explained by a balance between hardening and dynamic recovery in surface layers strongly depending on the gSFE and temperature.

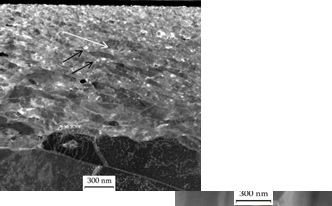

Typical HAADF STEM images of Ag presenting general view of deformation microstructure with a gradient of grain size. The white arrow shows direction of friction. Black arrows show the pores in top layers.