Dipanjana De

National Institute of Technology Agartala, India

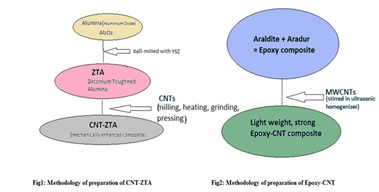

Title: Development of CNT-reinforced ceramic matrix composites for wear-resistance application and light- weight high strength CNT-reinforced epoxy composite

Biography

Biography: Dipanjana De

Abstract

The use of carbon nanotubes (CNTs) in the Zirconium Toughened Alumina (ZTA) matrix composite results in enhanced mechanical properties. In this study, the ceramic matrix composites – ZTA (containing 80 vol% of pure Al2O3 and 20 vol% of yttria stabilized zirconia (YSZ)) is furthermore mixed with different proportions of MWCNTs. The addition of YSZ in monolithic ceramic results in the reinforcement of the pure alumina Al2O3, thus overcoming brittleness of monolithic ceramics. It, too, results in corrosion resistance and temperature stability. The resulting reinforced composite is ZTA. Our main aim is to improve the mechanical properties of ZTA such as fracture toughness and micro-hardness. It is observed that CNTs are better than SiC for reinforcement. Due to its large aspect ratio (diameter Ì´ 20-30 nm and length Ì´ 1-2μm) and tensile strength, CNTs are the most preferred reinforcing material used for binary composites. Carbon fiber-reinforced epoxy composites modified with carbon nanotubes (CNTs) were fabricated and characterized. Here, Araldite is mixed with Aradur (hardener) to create a strong epoxy composite. Furthermore, MWCNTs are added in the composite to produce a light-weight, strong composite. A process for preparing carbon nanotube (CNT) dispersions for reinforcement of CNT in epoxy resin for improved mechanical properties has been reported. Mechanical property evaluations were then performed for the cured CNT-epoxy nano-composites and compared to the base epoxy resin matrix. This research may help to propose a further positive solution for fabricating CNTs-epoxy reinforced nanocomposites.

Recent Publications

1. Bocanegra-Bernal MH, Echeberria J, Ollo J, Garcia-Reyes A, Dominguez-Rios C, Reyes-Rojas A, Aguilar-Elguezabal A (2014) A comparison of the effects of multiwall and single-wall carbon nanotube additions on the property of Zirconia toughened alumina. Carbon 49:1599-1607

2. Echeberria J, Rodriguez N, Vanmeensal K, Reyes-Rojas A, Garcia-Reyes A, Dominguez-Rios C, Aguilar-Elguezabal A, Bocanegra-Bernal MH (2012) Hard and Tough carbon nanotube reinforced zirconium-toughened alumina composite prepared by spark plasma sintering. Carbon 50:706-717

3. Akin Ipek (2015) Investigation of the microstructure, mechanical properties and cell viability of zirconia-toughened alumina composites reinforced with carbon nanotubes. Journal of the Ceramic Society of Japan 123 [5] 405-413

4. Galusek Dušan, Galusková Dagmar (2015) Alumina Matrix Composites with Non-Oxide Nanoparticle Addition and Enhanced Functionalities. Nanomaterials 5: 115-143

5. Popov Valentin N. (2004) Carbon nanotubes: properties and application. Materials Science and Engineering R 43: 61–102