Alberto Monsalve

Universidad de Santiago de Chile, Chile

Title: Influence of temperature on mechanical properties of a Fe-22Mn-0,6C TWIP steel

Biography

Biography: Alberto Monsalve

Abstract

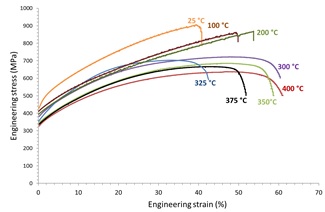

The objective of the present study is to analyze the microstructure and mechanical properties of a TWIP steel at different temperatures. For this purpose, tensile tests were performed in a Fe-22Mn-0.65C TWIP (Twinning-induced plasticity) steel in a temperature range between 25 °C and 400 °C. The microstructure after deformation was characterized via optical microscopy. It was observed that the microstructure consists of mainly deformation twins at low temperatures, whereas dislocation bands are the predominating feature at high temperatures. The yield stress, ultimate tensile strength, total elongation, strain hardening index and the area reduction were measured at different temperatures. The analysis of mechanical data suggests a transition of deformation mechanism from twinning at low temperature to dislocation slip at high temperatures. The work hardening rate and area reduction variations with temperature are discussed and correlated to the decrease of twinning contribution to the deformation mechanism. The role of other process, such as dynamic strain aging and precipitation hardening, are discussed. A thermodynamic-based description for the dependence of Yield stress with temperature was developed, suggesting two acting work hardening mechanisms. This is consistent with the computed activation energy for each mechanism. The stacking fault energy (SFE) was computed by means of Olson and Cohen model, at different temperatures finding that at temperatures higher than 325°C, dislocation glide was the predominant deformation mechanism, which is in accordance with experimental results. Twinning-volume fraction (TVF) in samples tested at different temperatures were computed, finding a decrease in TVF as testing temperatures increases, which in agreement with previous experimental features.

Recent Publications

1. B. De Cooman, Y. Estrin, S. Kim (2018) Twinning-induced plasticity (TWIP) steels. Acta Materialia 142: 283-362.

2. A. Saleh, A. Gazder (2016) A re-evaluation of “The micromechanics of twinning in a TWIP steel”. Materials Science and Engineering A 649:184-189.

3. E. Galindo-Nava, P. Rivera-Díaz-del-Castillo (2017) Understanding martensite and twin formation in austenitic steels: A model describing TRIP and TWIP effects. Acta Materialia 128:120-134.

4. B. De Cooman, O. Kwon, K. Chin (2012) State-of-the-knowledge on TWIP steel. Materials Science and Technology 28:513-527.

5. O. Bouaziz, S. Allain, C. Scott, P. Cugy, D. Barbier (2011) High manganese austenitic twinning induced plasticity steels: A review of the microstructure properties relationships. Current Opinion in Solid State and Materials Science 15:141-168.