Nobufumi Ueshima

Tohoku University, Japan

Title: Relationship between grain distribution and strain localization in Cu-Al alloys

Biography

Biography: Nobufumi Ueshima

Abstract

It has been highly demanded to miniaturize lead frames, sockets and any kind of connecting element made of copper or its alloys. Miniaturization increases the ratio of grain size to parts size. In such a case, individual grain size and orientation effect on the deformation behavior becomes significant, which causes ununiform deformation and decrease in formability. To understand the mechanism of the ununiform deformation in detail, strain localization during tensile test of oligo-crystalline Cu-Al plate has been investigated.

Cu-Al alloys were melted by induction furnace and cast into stainless steel mold. Dog-bone specimens were cut from the cast alloys. The cooling rate after casting was controlled to obtain various grain sizes, which enables us to see the effect of grain distribution on strain localization in visible scale by optical microscopy. Crystal orientation of the grains was analyzed by EBSD. A random pattern was painted on the surface of the specimen and the painted surface was recorded during tensile test to analyze strain distribution by digital image correlation (DIC) method.

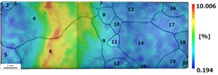

Figure 1 shows the equivalent strain distributions of the reduction section during tensile test. Nominal tensile strain calculated from DIC analysis was 0.1. Strain was localized in specific grains before reaching its highest strength. Schmid's factor of the grains was analyzed. We found that the strain does not always localize at high Schmid's factor grains. When high Schmid's factor grain is surrounded by low Schmid's factor grains, the high Schmid's factor grain cannot deform largely. In contrast, strain was localized relatively low Schimid's factor grains chained over the width of the specimen. In such a case, interlocking among grains seems to be relatively weak since the edge of the specimen can move freely, which may be the reason for the strain localization.

Figure 1: Strain Distribution of oligo-crystalline Cu plate at 0.1 of tensile strain. The black lines show the grain boundaries measured by EBSD. The numbers are grain index. We can see strain localization at grain 4 and 6.

Recent Publications

1. Ueshima N, Maeda T, Oikawa K (2017) Effect of Cu addition on precipitation and growth behavior of MnS in silicon steel sheets. Metall. Mater. Trans. A 48:3843-3851.

2. Ueshima N, Liu XT, Utsumi H, Chiyokubo T, Horio K, Oikawa K (2017) Influence of Cu and Mg addition on age-related deterioration in strength and creep behavior of Zn-12Al die casting alloy, Int. J. Mater. Res. (formerly Z. Metallkd.) 108:151-154.

3. Ueshima N, Yoshiya M, Yasuda H, Fukuda T, Kakeshita T (2015) Numerically-quantified two dimensionality of microstructure evolution accompanying variant selection of FePd. Mater. Res. Exp. 2:076502(13pages).

4. Ueshima N, Yoshiya M, Yasuda H, Fukuda T, Kakeshita T (2014) Impact of interplay between magnetic field, transformation strain, and coarsening on variant selection in L10-type FePd. J. Appl. Phys. 115:073501(10pages).

5. Ueshima N, Shikatani T, Yoshiya M, Yasuda H (2013) Effect of Spatial Distribution of Local Magnetization on Microstructure Formation in L10-type Ferromagnetic Alloys under External Magnetic Field. Trans. Mater. Res. Soc. Jpn. 38:673-676.