Philippe Da Silva

Valeo THS, France

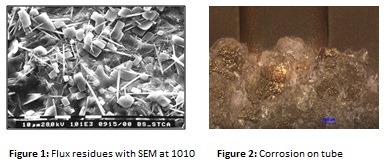

Title: Impact of the residual flux reduction on the internal corrosion behavior for the automotive brazed heater cores

Biography

Biography: Philippe Da Silva

Abstract

The Nocolok® flux is used in the worldwide technology of heat exchangers to remove the aluminum oxide during the controlled atmosphere brazing. This flux (mixture of Potassium (K), Aluminum (Al), Fluorine (F)) is known to react with corrosion inhibitors of coolants. Furthermore, the several temperature cycles, the coolant ageing and the inhibitors consumption have an impact on the internal corrosion behavior of heat exchangers. That is the reason why car manufacturers ask to reduce the residual flux amount inside parts. The challenge of VALEO is to minimize the flux quantity while maintaining a good brazing quality and also staying at high level of robustness and reliability. A method to quantify the residual flux inside exchangers has been developed. The impact of the residual flux reduction on the internal corrosion behavior has been studied thanks to an internal corrosion reliability test developed by VALEO. This test called DECLIC (Degraded Coolant for Internal Corrosion test) will give us the benefit or not to reduce the flux quantity inside parts during the brazing process.