Daniela Penther

Technische Universität Berlin, Germany

Title: Microstructural characterization of Mg-SiC nanocomposites produced by powder metallurgy techniques

Biography

Biography: Daniela Penther

Abstract

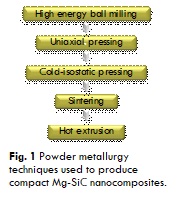

In the present study, the microstructure of newly developed magnesium matrix composites reinforced with SiC nanoparticles was investigated. To produce Mg-SiC nanocomposites, magnesium powder and various volume fractions of SiC particles with an average diameter of 50 nm were co-milled by a high energy planetary ball mill. The milled powder was compacted by a hydraulic hand-operated press followed by cold isostatic pressing and sintering. Finally, the nanocomposites were hot extruded to eliminate porosity and achieve full density. Scanning electron microscopy, energy dispersive x-ray analysis and x-ray diffraction were used to characterize the microstructure and texture of the magnesium matrix and the distribution of the SiC-reinforcements after extrusion. Further, transmission electron microscopy analyses were performed to study the grain size of the magnesium matrix and the interface between the SiC nanoparticles and the magnesium matrix. All developed nanocomposites revealed a uniform distribution of the SiC nanoparticles in the magnesium matrix. No evidence of porosity or interfacial products between the SiC nanoparticles and the magnesium matrix were found, indicating a well-bonded interface. The used powder metallurgy techniques allow to produce dense nanostructured Mg-SiC nanocomposites.