Anne-Gaëlle Villemiane

Valeo THS, France

Title: The determining role of brazing clad in aluminium material fatigue behavior for automotive exchanger applications

Biography

Biography: Anne-Gaëlle Villemiane

Abstract

Economic and environmental drivers are leading to exchanger weight reduction for automotive applications. The consequence is a material downgauging and some critical conditions reached. One of the exchanger’s main failure modes is induced by transient differential dilatations between the exchanger components. In this work, a detailed characterization of the cyclic damage mechanisms in car heat exchangers has been undertaken in order to improve their reliability.

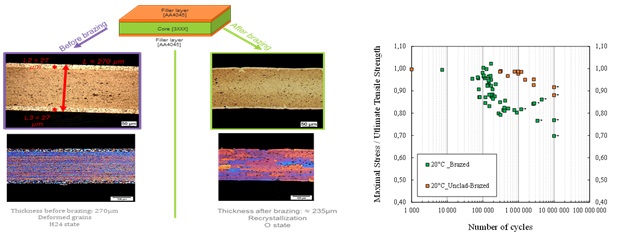

The studied material is a very thin (<0.3 mm) aluminum sheet composed of 3 layers (4XXX /3XXX/ 4XXX) (figure 1) compared to the same aluminium sheet made of 1 layer (3XXX), brazed in similar conditions to those of real components. Fatigue tests at constant stress amplitude have been performed at room temperature to show the influence of the clad in the fatigue resistance. Tensile properties between the clad alloy and the unclad alloy are strictly identical. However, the Wölher curve shows a high fatigue resistance for the unclad material compared to the cladded one. (Figure 2).

Fractography analysis on the 3 layer alloy reveals that the crack initiation is intergranular on the clad side and occurs on the specimen face because the clad is harder than the core which weakened the grain boundaries leading to multifissuration initiation and propagation. Cracks stopped for about 50% of the fatigue life then there is a transgranular propagation of the crack until failure. Concerning the unclad material, the elements Cu, Fe, Si, Mn and Ti are better distributed in the alloy thickness leading to a less modified surface state and decreasing the site initiation number and therefore the multifissuration. Thanks to microstructure, tomography and surface rupture analysis a fatigue damage mechanisms can be proposed, showing the residual clad layer key influence on the crack initiation.